Step-by-Step Guide to Battery Terminal and Lug Selection

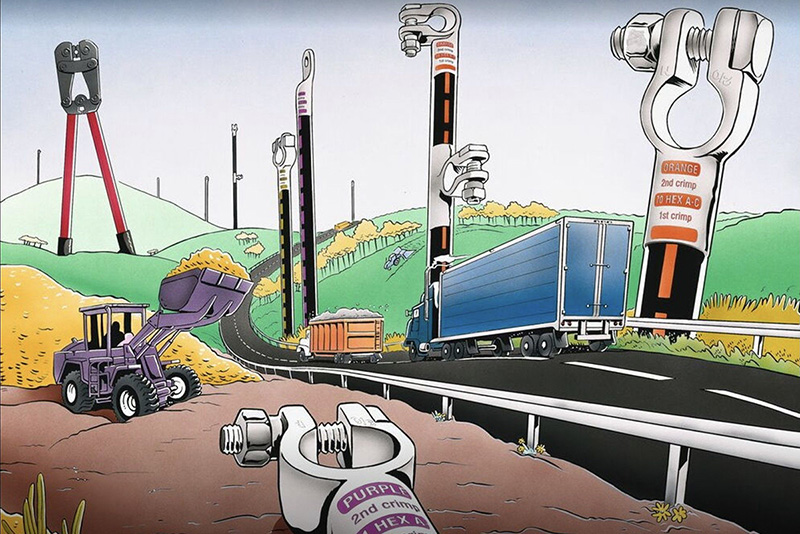

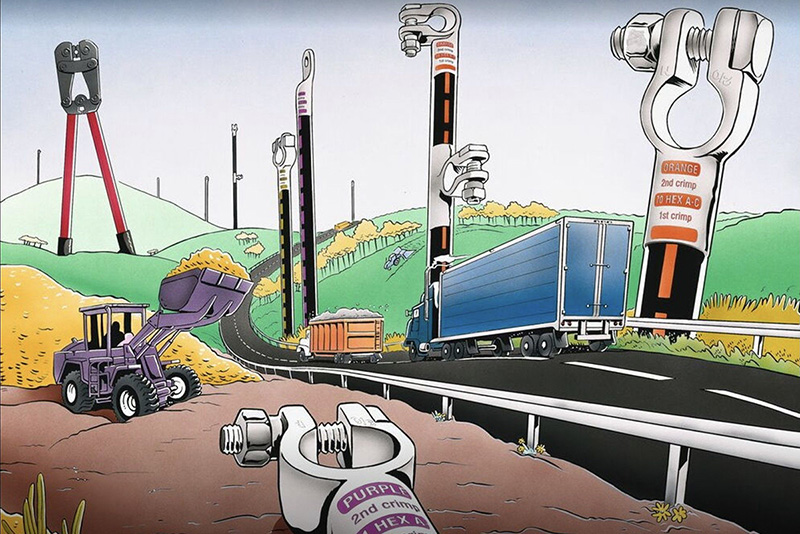

Understanding the significance of selecting the appropriate battery terminals and lugs cannot be overstated. These components play a pivotal role in maintaining peak battery performance and safeguarding the reliability of your electrical system. In this comprehensive guide, we will explore the different types of battery terminals and lugs, delve into the materials they are composed of, and provide a systematic process for their selection, ensuring a seamless and efficient operation of your equipment.

Importance of Proper Battery Terminal and Lug Selection

Before diving into the specifics, let's understand why selecting the right battery terminals and lugs matter. These components play a pivotal role in ensuring the smooth operation of your vehicle or machinery. Incorrect selection can lead to poor battery performance, electrical system issues, and even safety hazards.

Understanding Battery Terminals

Battery terminals come in various types, and each has its advantages and disadvantages. The three primary types are top post, side post, and universal.

- Top Post Terminals : These are the most common and are often found in traditional automotive batteries. They are versatile and can accommodate various cable attachments.

- Side Post Terminals : Typically used in newer vehicles, side post terminals are space-saving and provide a secure connection. However, they may not be as versatile as top post terminals.

- Universal Terminals : As the name suggests, universal terminals can work as both top post and side post terminals, offering flexibility in installation

Material options for battery terminals include lead, copper, and brass. Each material has its advantages and disadvantages, such as conductivity and corrosion resistance.

Evaluating Lug Types

Lugs are essential for connecting cables to battery terminals and other electrical components. The three primary lug types are ring lugs, spade lugs, and butt connectors. The choice depends on your application and preferences.

- Butt Splice Connectors : These are used to join two cables end-to-end. They are commonly used in automotive wiring and electrical repairs.

- Ring Lugs : These are circular in shape and provide a secure, ring-like connection. They are suitable for applications where a secure and reliable connection is crucial.

Here are some of the ring lugs available at Royal Brass and Hose:

- Angled ring lugs feature a bent or angled design, making them suitable for tight or awkward spaces where a straight lug may not fit comfortably.

- Locking ring lugs incorporate mechanisms like locking serrations to ensure a secure and reliable connection. These serrations securely hold the lug in place once it’s attached to a terminal, ideal for high-vibration environments or situations where accidental disconnection must be prevented.

- Solder type ring lugs have soldering surfaces or tabs, allowing for a permanent and highly reliable electrical connection, commonly used in applications requiring both mechanical and electrical stability.

- Compression type ring lugs utilize a barrel-shaped design and compression process to tightly secure the wire, creating a strong and low-resistance electrical connection, suitable for high-current applications

Lug materials include copper, aluminum, and tinned copper. The choice should be based on factors like conductivity and corrosion resistance.

Step-by-Step Guide to Battery Terminal and Lug Selection

Step 1: Assess your Equipment’s Power Requirements and Wire Gauge

Before delving into the selection of terminals and lugs, it’s imperative to thoroughly understand your equipment’s power needs and the wire gauge you’ll be using. Begin by evaluating the voltage and current requirements specific to your equipment or vehicle. Simultaneously, determine the appropriate wire gauge that aligns with your power demands.

Step 2: Battery Terminal Protection

To prevent corrosion and ensure a secure connection, use terminal protectors . These simple accessories protect your battery terminals from the elements and extend the battery’s lifespan.

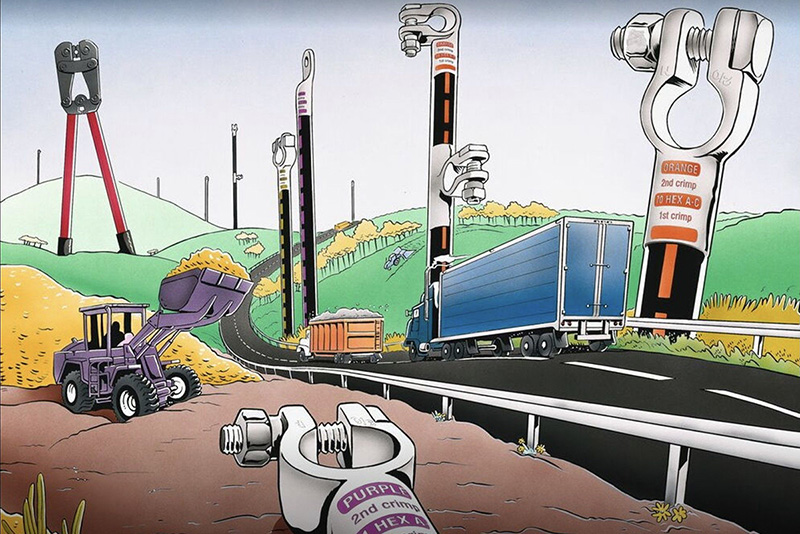

Step 3: Selecting the Right Lugs and Connectors

Lugs are essential for connecting cables to the battery terminals. Consider the following factors:

- Material: Lugs are available in various materials like copper, aluminum, and brass. Choose based on conductivity and corrosion resistance.

- Type: Depending on your project, you may need straight clamp connectors , right elbow connectors , left elbow connectors , or stud connectors .

- Size: Ensure the lug size matches the cable diameter and battery terminal size.

- Crimping and Soldering: Properly crimp lugs onto cables for a secure connection. Then employ proper soldering techniques to ensure a more corrosion resistant and electrically conductive connection. This is an imperative step, especially in high ampere situations.

Step 4: Heat Shrinkable Tubing

Heat shrinkable tubing is used to protect and insulate cable connections. Slide it over the lug and cable joint, then apply heat to shrink it into place, providing additional protection against moisture and damage.

Step 5: Butt Splice Connectors

A properly installed and well-executed butt splice connectors can provide a strong and reliable bond between two cables. Here's how to make the most of them:

- Assess the Situation : Before opting for a butt splice connector, assess your project's specific requirements. Consider factors such as cable length, availability of replacement cables, and the need for a permanent or temporary solution.

- Proper Installation : When using butt splice connectors, ensure they are properly installed. This typically involves crimping, soldering, and heat shrink tubing.

- Consider Replacement Cables : If you're dealing with severely damaged cables or if the cost of the butt splice connectors and labor is comparable to the price of a new cable, it may be more practical to purchase a replacement cable altogether. Assess the overall cost-effectiveness of the solution.

Step 6: Battery Connector Accessories

Various accessories can enhance your battery and lug setup:

• Cable ties and clamps help organize and secure cables.

• Terminal covers protect exposed terminals.

• Battery trays and hold-downs keep the battery securely in place.

• Battery testers and chargers help maintain battery health.

Step 7: Battery Cables

Select high-quality battery cables with the appropriate gauge and length for your application. Ensure they are properly crimped to the lugs for a reliable connection.

Curious on how to assemble a battery cable? Check out this video: How to Assemble a Battery Cable.

Proper Techniques for Crimping, Soldering, Heat Shrinking, and Tightening

In the process of selecting the right lugs, connectors, and ensuring a reliable electrical connection, it's equally crucial to pay attention to the techniques you use. Here are some essential tips for achieving secure and durable connections:

Crimping Techniques:

- Use the appropriate crimping tool : Invest in a high-quality crimping tool that matches the lug or connector size you are working with. Avoid using pliers or other makeshift tools.

- Strip wires properly : Ensure that the wires are stripped to the correct length as recommended by the lug or connector manufacturer. Exposed wires that are too long can lead to poor connections.

- Position the lug correctly : Slide the lug onto the wire so that it covers the stripped portion entirely, leaving no exposed wire.

- Apply uniform pressure : When crimping, apply even and firm pressure across the crimped area to create a secure and tight connection.

- Inspect the crimp : After crimping, inspect the connection to ensure there are no visible gaps or loose wires.

Soldering Techniques:

- Clean and flux the wires : Prior to soldering, clean the wires to remove any oxidation or contaminants. Apply flux to improve solder flow and adhesion.

- Use the right soldering iron : Choose a soldering iron with the appropriate wattage for the job. A temperature-controlled iron is ideal for precise soldering.

- Apply solder sparingly : Apply just enough solder to create a strong bond without excessive buildup. Excess solder can lead to poor connections or shorts.

- Allow proper cooling : Let the soldered joint cool naturally, avoiding any movement until it has solidified.

Heat Shrinking Techniques:

- Choose the correct heat shrink tubing : Select tubing that fits snugly over the connection and is large enough to accommodate the lug or connector.

- Apply heat evenly : Use a heat gun or other appropriate heat source to evenly shrink the tubing. Avoid overheating, which can cause damage or deformation.

- Ensure a sealed connection : Verify that the heat shrink tubing completely covers the connection and forms a tight seal. This protects against moisture and damage.

Tightening Techniques:

- Use the proper tools : When securing lugs or connectors to terminals or studs, use the correct tools for the job. A torque wrench is ideal for achieving the recommended tightening torque.

- Follow manufacturer guidelines : Consult the lug, connector, or terminal manufacturer's guidelines for the recommended torque specifications. Over-tightening can damage components, while under-tightening can result in loose connections.

By following these techniques, you'll enhance the reliability and longevity of your electrical connections, ensuring they perform optimally and withstand the test of time.

Tips for Battery Terminal and Lug Maintenance and Care

- Regular Inspection and Cleaning : Periodically inspect battery terminals and lugs and clean them to prevent corrosion buildup.

- Anti-Corrosion Products : Apply anti-corrosion products to extend the lifespan of your terminals and lugs.

- Tight Connections : Ensure all connections are tight and address any issues promptly to prevent electrical problems.

Common Battery Terminal and Lug Mistakes to Avoid

- Mixing Incompatible Terminal and Lug Types : Stick to compatible types to avoid fitment and connection issues.

- Using Incorrect Sizes or Gauges : Always match the size and gauge of terminals, cables, and lugs to ensure a proper fit.

- Neglecting Proper Crimping or Tightening Techniques : Invest in quality crimping tools and follow the correct procedures for secure connections.

Conclusion

Choosing the right battery and lugs is essential for the performance and safety of your electrical or automotive system. By following this step-by-step guide and considering factors like power requirements, materials, and accessories, you can confidently select the best products for your project. Remember, proper installation and maintenance are also crucial to ensure the longevity and reliability of your battery and lug setup.

Need Help Selecting the Right Battery Terminal or Lug?

When it comes to battery terminals and lugs, we’re trusted experts. Contact us or call 800-669-9650 to speak with a member of our customer service team at any of our 11 locations (Knoxville, TN; Marietta, GA; Orlando, FL; Charlotte, NC; Little Rock, AR; Fort Worth, TX; Benton, IL; Madisonville, KY; Princeton, WV; Birmingham, AL; Calvert City, KY).